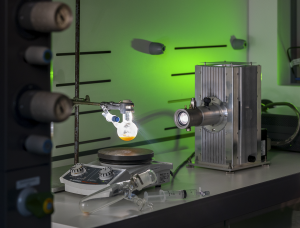

Inspired by nature: The new developed “nanozyme” mimics the properties of enzymes involved in photosynthesis. (Photo: Astrid Eckert / TUM)

Plants use photosynthesis to harvest energy from sunlight. Now researchers at the Technical University of Munich (TUM) have applied this principle as the basis for developing new sustainable processes which in the future may produce syngas (synthetic gas) for the large-scale chemical industry and be able to charge batteries.

Syngas, a mixture of carbon monoxide and hydrogen, is an important intermediate product in the manufacture of many chemical starter materials such as ammonia, methanol and synthetic hydrocarbon fuels. “Syngas is currently made almost exclusively using fossil raw materials,” says Prof. Roland Fischer, from the Chair of Inorganic and Organometallic Chemistry.

A yellow powder, developed by a research team led by Fischer, is to change all that. The scientists were inspired by photosynthesis, the process plants use to produce chemical energy from light. “Nature needs carbon dioxide and water for photosynthesis,” says Fischer. The nanomaterial developed by the researchers imitates the properties of the enzymes involved in photosynthesis. The “nanozyme” produces syngas using carbon dioxide, water and light in a similar manner.

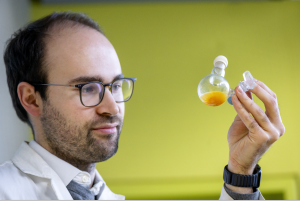

Generating energy from light: Dr. Philip Stanley from TU University with the newly developed “nanozyme”. (Photo: Astrid Eckert / TUM)

Dr. Philip Stanley, who addressed the topic as part of his doctoral thesis, explains: “A molecule takes over the task of an energy antenna, analogous to a chlorophyll molecule in plants. Light is received and the electrons are passed on to a reaction center, the catalyst.” The innovative aspect of the researchers’ system: There are now two reaction centers which are linked to the antenna. One of these centers converts carbon dioxide into carbon monoxide, while the other turns water into hydrogen. The major design challenge was to arrange the antenna, the mechanism for passing on the electrons and the two catalysts, in such a way that the highest possible yield is achieved from the light. And the team accomplished this. “At 36 percent, our energy yield from light is spectacularly high,” says Stanley. “We succeed in converting as much as one third of the photons into chemical energy. Previous systems often attained every tenth photon at best. This result raises hopes that the technical realization could make industrial chemical processes more sustainable.”

In a separate project the researchers are working on another material which uses light energy from the sun – but in this case stores it as electric energy. “One possible future application could be batteries which are charged by sunlight, without the detour through the wall socket,” says Fischer. The researchers used components similar to those in the nanozyme when developing these photo accumulators. Here too the material itself absorbs photons from the incident light. But instead of then serving as a catalyst for a chemical reaction, the energy receiver is so tightly integrated in the structure that it remains in this state, making storage of the electrons over a longer period of time possible. The researchers have demonstrated the feasibility of the system in the lab. “There are two ways to make direct use of solar energy,” summarizes Dr. Julien Warnan, group leader for photocatalysis. “Either we harvest electric energy from it or we use the energy to push chemical reactions. And these two systems, both based on the same principle, show that we’ve succeeded experimentally.”