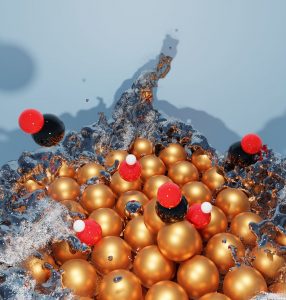

Artistic view of the dynamically restructuring catalyst surface (A. Auer)

Even for experienced catalysts, matchmaking is not always easy. Some partners bind to strong, others leave too early… A team of scientists including members of e-conversion now observed how a copper electrode solves this problem all by itself.

Scientists from the University of Innsbruck and the Theory Department of the Fritz-Haber-Institute find highly dynamic structural changes at the surface of working Copper electrocatalysts. These changes turn out to be key to the high performance and could be a design target for future improved catalysts.

Catalysts accelerate chemical reactions and thus make them useable for large-scale technological applications. They are needed not least for a sustainable supply of energy, for they are at the core of fuel cells that convert chemical into electrical energy. Efficient catalysts are also important for splitting water into hydrogen or producing synthetic fuels. Unfortunately, presently these catalysts often consist of rare and very expensive elements such as platinum or iridium, so that catalysis research is looking for more abundant alternatives.

The search is aided by the century-old Sabatier Principle. It states that a good catalyst material should bind the participating molecules strong enough to activate them for the reaction, but still weak enough to not hold on to them forever. Most reactions need catalysts that selectively bind certain molecules stronger and others weaker. Unfortunately, many materials tend to bind different molecules either too strong or too weak. Studying the electro-oxidation of carbon monoxide (CO), a team around e-conversion member Prof. Karsten Reuter (TU München and Director at the Fritz-Haber-Institute, Berlin) and Prof. Julia Kunze-Liebhäuser from the University of Innsbruck discovered that copper (Cu) catalysts have their own solution to this problem. Their work was recently published in Nature Catalysis.

Carbon monoxide sometimes forms as an unwanted by-product during the generation of hydrogen. A huge problem arises when CO comes along into a fuel cell: The molecules block active catalyst sites and thereby “poison” the cell. One way to get rid of the troublemakers is their electro-oxidation into carbon dioxide (CO2) – here catalyzed by a copper electrode in an alkaline electrolyte. During the reaction, the scientists observed that the copper surface is continuously converted and that small islands of a few copper atoms are formed. The charge of adsorbing ions gets stored in these protruding, nanometer-sized clusters. In the studied electro-oxidation reaction in the used alkaline electrolyte this is especially the charge of the involved hydroxide (OH–) ions. This leads to fundamentally different binding properties to the catalyst than for the neutral reaction partner CO. The hydroxide ions are bound weaker, the CO stronger – exactly the mixture required for the observed high catalytic activity.

The possibility of changing the binding strength separately and individually for neutral and charged molecules through cluster-like protrusions on the catalyst’s surface could represent a completely new approach to fulfilling the Sabatier Principle. On copper these clusters form spontaneously during the dynamic restructuring of the surface under reaction conditions. In the future, one might want to create them deliberately via rational catalyst design.

Source: Fritz Haber Institute of the Max Planck Society / e-conversion

Publication

Self-activation of copper electrodes during CO electro-oxidation in alkaline electrolyte. A. Auer, M. Andersen, E. Wernig, N. G. Hörmann , N. Buller, K. Reuter, J. Kunze-Liebhäuser. Nat Catal (2020). https://doi.org/10.1038/s41929-020-00505-w

Contact

Prof. Karsten Reuter

Director, Theory Department

Fritz Haber Institute of the Max Planck Society

reuter@fhi-berlin.mpg.de